Plasma Arc Thermal Spraying

Plasma Arc Thermal Spraying

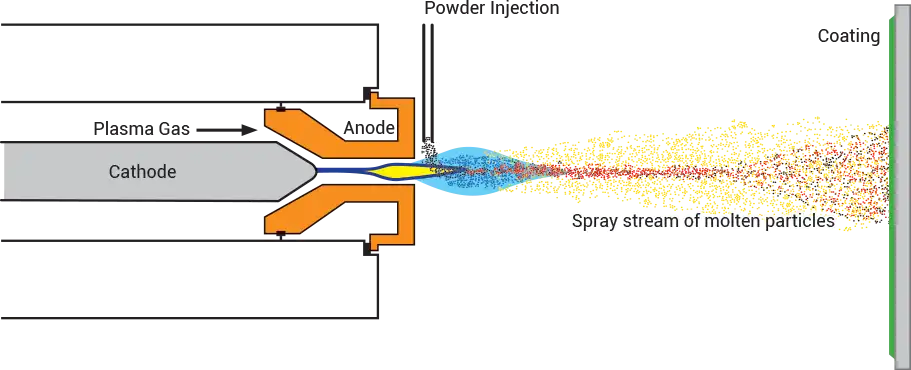

The plasma gun is comprised of a copper anode and tungsten cathode, both of which are water-cooled. The plasma gas, typically argon, nitrogen, hydrogen, or helium, flows around the cathode and through the anode, which is a constricted nozzle. The plasma is initiated by a high voltage discharge that causes localized ionization and a conductive path for a DC arc to form between the cathode and anode.

The resistance heating from the arc causes the gas to reach extreme temperatures, dissociate and ionize to form plasma. The plasma exits the anode nozzle as a free or neutral plasma flame or plasma which does not carry electric current. This is different than the Plasma Transferred Arc coating process, in which the arc extends to the surface to be coated.

When the plasma is stabilized and ready for spraying, the electric arc extends down the nozzle, instead of shorting out to the nearest edge of the anode nozzle. This stretching of the arc is due to a thermal pinch effect. Cold gas around the surface of the water-cooled anode nozzle being electrically non-conductive constricts the plasma arc, raising its temperature and velocity. Powder is fed into the plasma flame most commonly via an external powder port mounted near the anode nozzle exit.